British refusal to co-operate with the MOROP body precluded any common standards body, and 4mm scale with 16.5mm gauge developed in isolation. In America 4mm scale is recognised, with 19mm gauge, but is too close to H0 to command a following, and is virtually defunct.

In 1945 an opportunity existed for a fresh start to be made, but the Trade members who constituted the bulk of the new British Railway Modelling Standards Bureau were against change, and the standards simply became a vehicle for the maintenance of the pre-war practices, with a gesture towards correct proportions in the form of EM Gauge.

Although EM Gauge has never been properly catered for by the Trade, it nevertheless attracts a large following. Although the eighteen millimeter track gauge is the nearest approach to correct scale modelling in the 4mm scale BRMSB standards, it is incorrectly proportioned in that the gauge represents only 4ft 6in instead of the 4ft 8½in of the prototype, and wheels and rail are to the BRMSB compromise standards.

Close-to-scale wheels, with 2mm tyre width, will operate correctly on EM Gauge track (2.5mm wheels are mandatory on 00 and H0 gauge tracks) and several EM gauge modellers decided to experiment with correct track gauge and 'Manchester’ wheels in an attempt to produce correctly scaled model railways in 4mm/ft scale. The results of the 'EEM’ experiments were encouraging, and eventually a study group was formed to investigate matters thoroughly. Initially studies were based on a development from BRMSB towards correct scale, but as these approaches invariably led to restrictions, the entire Greenly philosophy was abandoned and a completely fresh start made, working from prototype practice.

It is necessary in designing a scale model railway to define the word 'Scale’, a word sadly misused and overworked in commercial applications. A scale model is one that has been made to a Constant Proportion of full size. The terms 'Dead Scale’, 'True Scale’ and 'Authentic Scale’ imply that a model is correct in all dimensions and detail. On the other hand, Commercial 'Scale’ models often convey only the general appearance of the prototype, and are not necessarily to any particular or even constant scale.

'Protofour’ is the result of the Study Group’s endeavours and is the first complete and integrated table of standards to appear in Britain in connection with Model Railways. Protofour is so called as it is a complete breakaway from the past, the standards being derived from the prototype and applied to 4mm scale.

The Study Group was faced with four main tasks, namely:

1. The tabulation of small scale railway modelling requirements.

2. The choice of a suitable scale for modelling operations.

3 The development of a table of working dimensions.

4. The introduction of a programme of tooling for gauges and components.

These tasks are best described separately.

Modelling Requirements

The primary failure of the BRMSB specifications is that they cover the secondary dimensions without first establishing the primary ones of wheel and rail contour. In the prototype, the contour of wheel treads and rail head is laid down in British Standard Specifications. Careful checks ensure that the wheel contour does not wear beyond specified amounts before the contour is re-turned in the shops. This control of contours is not practised in the BRMSB operations, and manufacturers are free to produce rail and wheels to their own contours, with no responsibility for the results. The contours of wheel and rail form an interacting pair of surfaces that determine the balance of the remaining dimensions. Thus a wheel only slightly different to another in appearance may have completely different running characteristics. Protofour wheels are designed to run with correctly contoured rail and both components are the subject of manufacturing drawings.

A further feature of prototype operations is the deliberate widening of track gauge on curves, progressively to ¾in on curves of less than five chains radius. (On LTE. lines, incidentally, the track gauge for straight track may be only 4ft 8-3/8in). This variation of gauge is also incorporated in the Protofour standards, thus allowing greater flexibility of operation of rigid wheelbase vehicles compared with BRMSB or commercial systems, where the track gauge is nominally constant.

Protofour has a further advantage over these systems in the adoption of prototype flange depths. The considerable variations in flange depths between the model wheels currently sold over the counter accounts for variation in running over the exaggerated curvature of model railways.

|

|

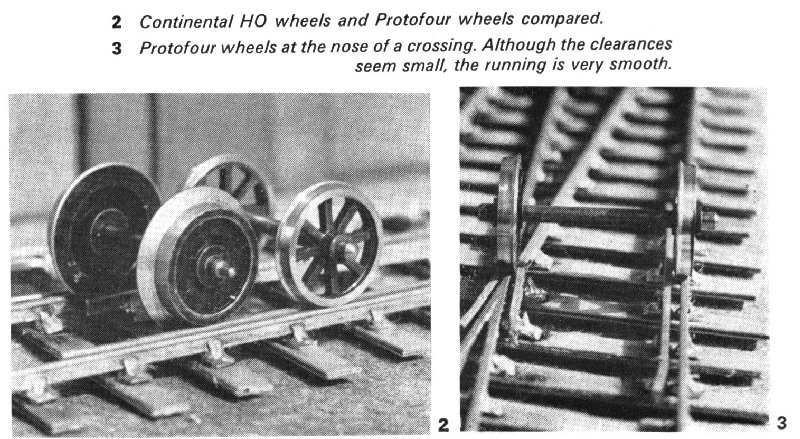

| 2 Wheels make a considerable difference to the appearance of a typical kit built coach, provided the wheels are of the correct proportions. | 3 Part of a Protofour test track, showing a turnout with scale crossing flangeways and model check rail spacing. Kings Cross rail and Brook Smith track system. The track assembly is to be modified in further production to offer correct scale appearance. |

Completely reliable track and wheel relationships require five dimensional controls:

1. Both wheel and rail contours must be of the correct pattern for

the standards used.

2. Wheel spacing on the axle --- Back to Back --- (or BB) must be correct.

3. Track Gauge --- (TG) --- must not be less than the nominal value.

4. Check Gauge --- (CG) --- measured from the face of the check rail to the face of the

outer running rail, must not be less than the nominal value.

5. Crossing Flangeway --- (CF) --- between the wing rails and the vee at a crossing, must

be the specified value.

From these checks it will be noted that all the dimensions are derived from the wheel and rail contour specified in 1 above. Also, contrary to established model practice, there is a difference between the flangeway at a check rail and the flangeway at a crossing. This is because the check rail is set in relation to the outer running rail, and has no relation to the adjacent rail; the check flangeway is simply the difference between Check Gauge and Track Gauge at that particular point.

Choice of scale

Much of the present confusion in modelling standards is caused by the adoption of mm/Ft scales in preference to the system of proportions. This is plainly seen in the Comparison Tables, where the mm/Ft scales and the ratio are set alongside each Scale.

In choosing a suitable scale for Protofour, it was desirable to avoid confusing the existing systems, yet to take advantage of current equipment where this met the modeller’s needs. Thus 4mm/ft scale was a natural choice, though the standards can be translated to any other scale to give authentic modelling as desired.

Table of Working Dimensions

This Table is included with this article, and the Protofour Standards shown are the final figures, checked and justified, which will remain unaltered from now onwards. These figures replace the 'EEM’ and other experimental figures that have appeared in the model press in the past few years.

LEADING DIMENSIONS |

|||||||

| NOMINAL | 4MM EQUIVAL'T | M.M. | INCHES | ||||

|

TG | TRACK GAUGE | 4' 8½" |

18.83 |

18.83 |

.741 (G) |

MIN |

| GW | GAUGE (A) WIDENING | ¾" |

.25 | .22 | .009 | NOM. | |

| CG | CHECK GAUGE | 4' 6¾" |

18.25 | 18.15 | .715 (G) | MIN | |

| CF | CROSSING FLANGEW'Y | 1¾" |

.58 | .68 (B) .65 |

.027 (G) .026 |

MAX MIN |

|

| R (o) | RAIL | RAIL HEAD SECTION - BS 95R EQUIV |

|||||

| P (o) | WHEEL | WHEEL CONTOUR - BS 276A EQUIV. |

|||||

| BB | BACK TO BACK | 4' 55/8" |

17.87 | 17.67 | .696 (G) | MIN | |

| BB+EF | CHECK CLEARANCE | 4' 63/8" |

18.25 | 18.15 | .715 | MAX | |

| TW | TYRE WIDTH | 5½" |

1.83 | 2.00 1.85 |

.079 .073 |

MAX MIN |

|

| EF | EFFECTIVE(C) FLANGE | 11/8" |

0.38 | 0.40 | .016 | MAX | |

NOTES: (A) AT 528MM. RADIUS. (B) PREFERRED DIMENSION. (C) REPLACES ACTUAL FLANGE IN COMPILATION OF STANDARDS. (O) SEE DIAGRAMS P4:1 AND P4:2. (G) GAUGE CONTROL. |

|||||||

It will be seen that a wheel of prototype proportions has been adopted, and in view of the current beliefs held in the hobby it must be expected that some criticism will be made to the effect that such 'fine’ proportions are unworkable. It has been interesting to examine the clearances involved in the various BRMSB standards and to find that Protofour is less critical than '00' in certain important situations. However, these matters are best discussed in a separate article.

Tooling and Gauges

The five checks of track and wheel dimensions listed earlier in this article must be achieved either through being incorporated into the components during manufacture, or through the use of gauges by the modeller.

Protofour became a practical proposition with the introduction of Kingsway’ scale bullhead rail in 1965. This is the only rail on the market which has both scale proportions and a correct rail head contour, and the only rail which can be used for Protofour modelling. It can, of course, be used for any other track system and will improve the appearance of BRMSB layouts whenever it is used.

The protofour wheel is based on the prototype and is produced either as a new wheel, or as a modification of current wheels by the use of a form tool. The form tools are made as a production tool for the commercial production of wheels.

There are four gauges for the modeller to use, namely track gauge: check gauge; wheel BB gauge and crossing flangeway gauge. Whether the modeller adopts Protofour or other standards, these gauges should be his basic equipment. The Protofour track gauge incorporates gauge widening in its threepoint construction.

|

|

Conclusion

Protofour represents a complete breakaway from past modelling practice. In order to operate the standards correctly, it will be necessary for the modeller to build reasonably level track and to incorporate some form of compensated suspension into the vehicles. Using correct techniques, these features are easily implemented and are in any case characteristic of the prototype. On reflection, there is no sound engineering reason why the malpractice of rigid wheel suspension should be continued. The new standards represent a technical advance on present commercial equipment. As components are designed specifically to work with one another, and dimensions are controlled during production, there is no reason why prototypical reliability factors should not obtain. When each critical dimension is checked by a gauge, there is no doubt about clearances; either the components accepts the gauge or it requires adjustment.

This control of dimensions both in manufacture and construction is the key to successful scale modelling. Those whose experience with current standards and equipment leads them to believe that so-called fine-scale’ is impracticable have reason now to reconsider their views. The choice of modelling scales is the prerogative of the modeller, but there is now, for the first time. the opportunity to build a really scale model railway with every probability of success. We in the Study Group believe that this is an opportunity that few serious modellers will be able to resist, and that Protofour will, in the long run, become the accepted scale modelling standard.

[Part 2 will appear next month]

Copyright - Model Railway Study Group, reproduced with permission.

Back to Magazine Index, Back to Site Index.

K Norgrove 16/9/01