Click on any thumbnail for a larger picture.

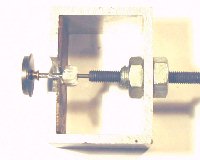

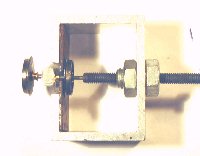

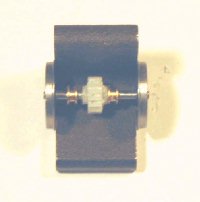

For the class 44 there are only two screws as shown in the second photo, and in this case no clips so the shell lifts straight off once the screws are out. All these screws are of the crosshead pattern but I have not found the crosshead drivers to fit well and have used a jewellers flat blade driver with more success.

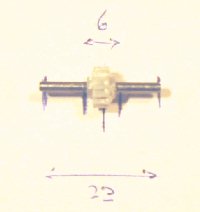

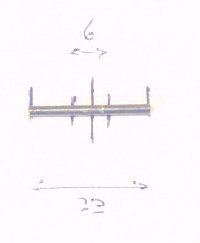

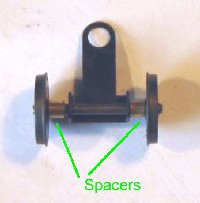

Once the shell is off bogies can be released by removal of the pivot screw shown in photo 3. I suggest removing only one bogie at a time. There is no need to remove the wires from the circuit board as there is enough slck to work on the bogie. (Note: if the bogies are removed from the 44 its a bit of a juggle to get the drive shaft back into place, if this worries you leave the bogie in place, it just needs a bit more care to unclip the bogie frame.

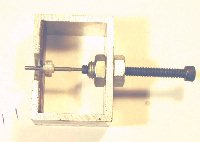

The outer cosmetic frames are fixed to the inner gearbox by a clip at each end. For the 24/25 I have found it easiest to unclip from the outer end using a small screwdriver. For the 44 the pony truck should first be unscrewed as the screw helps retain the outer end of the cosmetic frame, then unclip from the inner end. With the bogies fully rotated this can be done fairly easily without releasing the bogie. When the cosmetic frame is released the inner idler wheels will likely drop out along with their bearing saddle and spring, keep the bearing saddle and spring safe for use when re-assembling.